Canning St, Kolkata, West Bengal

- GST NO. : 19ADKFS4818F1ZR

Oil Burner

Leading Manufacturers, Exporters and Retailer of 5114 Series Oil Burner, 5172 Series Oil Burner and 5253 Series Oil Burner from Kolkata.

| Business Type | Manufacturer, Exporter, Retailer, Wholesaler |

| Material | Stainless Steel |

| Application | Industrial |

| Color | Black |

| Feature | Non Breakable, Rust Proof |

| Working Pressure | High Pressure |

| Installing | Portable |

| Download |

Preferred Buyer From

| Location | Worldwide |

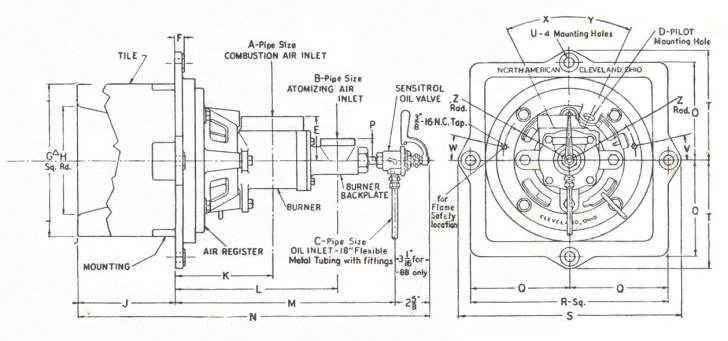

SAIFEE 5114 OIL BURNERS

are sealed-in burners for light or heavy oil used for a wide variety of industrial applications. These burners are capable of efficient operation throughout a wide range of preheat air temperatures, and are equally stable on low temperature ovens as well as high temperature furnaces for reheating, forging, melting, drying etc. The sealed mounting stops unwanted air from the atmosphere from entering the burner, which helps maintain furnace pressure, controlled atmosphere and better oil/air ratio for improved product quality. Saifee burners are stable with 100% or more excess air. They can be turned down to atomizing air only, but stability limits vary depending onburner size and grade of oil. For prolonged operations with only atomizing air at temperatures above 850 degree C, please specify an alloy burner nose.

Graph

| Business Type | Manufacturer, Exporter, Retailer, Wholesaler |

| Material | Stainless Steel |

| Application | Industrial |

| Color | Black |

| Feature | Non Breakable |

| Working Pressure | High Pressure |

| Installing | Portable |

| Download |

Preferred Buyer From

| Location | Worldwide |

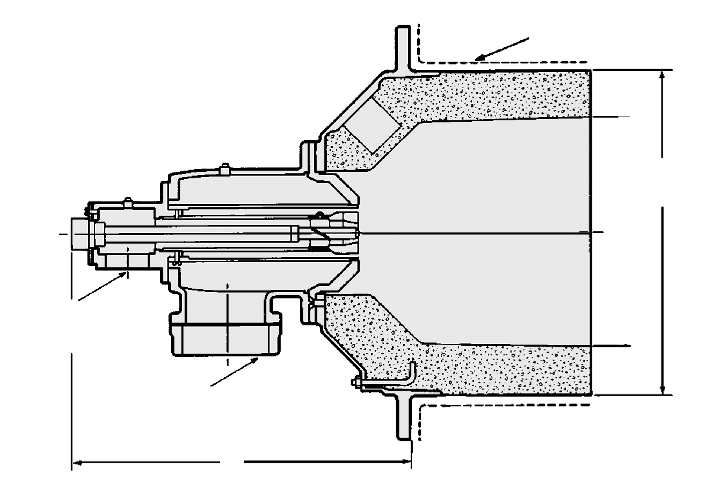

SAIFEE SERIES 5172 OIL BURNERS

are sealed-in, nozzle mix burners for distillate oil (100 SSU viscosity maximum) that are stable with excess air or up to 50% excess fuel (provided additional air for complete combustion is in the furnace near the burner).

TEMPERATURE UNIFORMITY

Excess air can improve temperature uniformity by avoiding hot spots in front of burners, by churning furnace atmosphere to reduce stratification, and by creating positive furnace pressure to eliminate cold air infiltration.

Graph

| Business Type | Manufacturer, Exporter, Retailer, Wholesaler |

| Type | Oil Burners |

| Diameter | 3-5inch, 5-7inch |

| Installing | Portable |

| Pack Type | Corrugated Box |

| Finishing | Color Coated |

| Size | 3 inch |

| Download |

Preferred Buyer From

| Location | Worldwide |

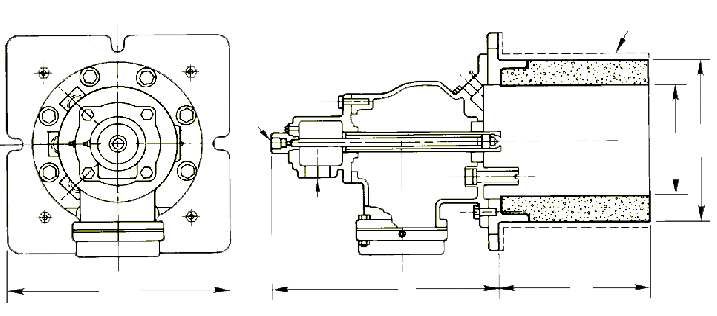

SAIFEE SERIES 5253 OIL BURNERS

are designed to give maintenance-free operation using heavy oil or light oil. There are no "frills" on this burner — it has a heavy cast iron body with a clean design that avoids clogging even when used on tough jobs such as forge furnaces fired with heavy oil.

BURNER CAPACITY

Total air capacity of the burner is listed under Table 1 for a single blower supplying 12 osi combustion air and 14 osi atomizing air for lightoil operation, and 20 osi combustion air and 22 osi atomizing air for heavy furnace oil operation. Use Table 2 and 3 when selecting separate blowers for combustion and atomizing air. For sizing of blowers or burners at other pressures, add figures from Table 2 and 3 to get total capacity. On oil operation these capacities are increased 20% by the additional air supplied through the atomizing air connection. When burning with the shutter open, burner capacities may be doubled if furnace conditions ensure sufficient secondary air.

BURNER OPERATION

Oil with viscosity of 70 to 90 Seconds Redwood 1 and a pressure between 25 and 30 psi shouldbe supplied to an Air/Oil Ratiotrol which will deliver oil to the burner at pressure proportional to the main air pressure, thus maintaining the correct air/oil ratio at all firing rates. Atomizing air pressure at the burner may be as low as 14 osi when using distillate oil and 22 osi when using heavy oil.

BURNER CONSTRUCTION

The heavy cast iron body can withstand rough handling. All internal parts of the 5253 burner are machined. The smooth surface stays free of oil deposits and dirt, greatly minimizing the need for cleaning. Oil is put through the burner in a straight passage with large cross-sectional area permitting visual inspection for clogging and easy clean-out if necessary. The burner oil valve is the well known Saifee sensitrol, a nonplugging V-port oil valve which produces small and uniform flow rate changes throughout the 180º sweep of the control handle. with a clean design that avoids clogging even when used on tough jobs such as forge furnaces fired with heavy oil.

Graph